A frequent question Total Green Recycling gets asked is “What happens to all those materials recovered from recycled electronics?”

There are over 90 different types of materials used in electronics. And contradictory to a popular belief, it’s not all precious gold and easily sold copper. It’s mainly metals and plastic – many different types of it. There are also Hazardous materials like lead, cadmium and mercury and even liquids like ink, coolant and oil. The hazardous materials and liquids cost money to be recycled in a controlled manner by other specialised recyclers. From glass and wood to fluorescent light globes, e-waste can contain almost anything. And it all gets recycled in different ways!

What we do here at Total Green Recycling is separate each material using our specialised plant. Each electronic item is a complex mixture of many material streams, and our recycling plant separates this complex item into recyclable waste streams, with minimal contamination. Each waste stream is then sent off for further processing.

So let’s have a look at some of the major material types recovered from e-waste during our recycling process.

Ferrous metals

Approximately 40% of e-waste is made up of ferrous metals namely steel. Steel is often used as the structural element in a device. For example, as the casing around PCs or the chassis of flat screens and printers.

Steel is an alloy of iron and carbon. Our magnet belt pulls out large ferrous metals while our steel line pickers ensure any contamination is removed from the material stream enabling the recovered steel to be exported directly.

We produce clean shredded ferrous metals which we then send downstream to be smelted and return it to the manufacturing industry. Due to the lack of a local steel smelting facility, Steel is exported to other countries.

Currently, there is only one smelter in WA that we know of. The smelter is located in Kalgoorlie and refines nickel. Due to lack of local manufacturing facilities many of our material streams are sent offshore. However instead of sending unprocessed and contaminated materials that can have negative environmental impacts, we send high quality and regulated materials. It is no different to exporting iron ore, or other virgin commodities.

Non-ferrous metals

Non-Ferrous metals do not contain iron and are generally more malleable metals. Such as Aluminium, copper and brass. These metals are recovered in three stages:

- The items go through the primary shredder

- Other materials such as steel are removed via a magnet, making the manual sorting process easier

- They are then manually sorted via the picking line

- The remaining items are picked up by the eddy current separator, which uses a high frequency vibration to separate non-ferrous metals from the other materials.

Aluminium

Aluminium has a number of material properties that are desirable for electronic manufacturers including:

• durability

• being lightweight

• high thermal conductivity

• recyclability

For this reason, it is found in the majority of electronics with some notable examples being structural elements in flat-screen TVs, motor housings and heat sinks.

Our process maximises material recovery and minimises potential environmental harm by ensuring our recovered aluminium is free of excessive contamination with other materials such as plastic.

The aluminium we recover is sent to a local scrap metal merchant where it is baled and exported overseas for further refining.

Aluminium can be infinitely recycled. Which is why it’s so important to keep e-waste out of landfill, as this amazing recyclable resource would be completely wasted. Recycling aluminium uses approximately 5% of the energy required to make new aluminium from bauxite.

Not only is transforming bauxite into aluminium incredibly energy-intensive, it also results in the production of a caustic bauxite residue which poses some environmental challenges to overcome.

If you’d like to learn more read this bonus article: Addressing the Challenge of Bauxite Residue

Copper

This salmon-coloured metal is usually found in anything where thermal conductivity is important, like heating and cooling, including:

• radiators, found in air-conditioners

• heat sinks, found in computers

• Compressors found in refrigerators

It’s also used because of its electrical conductivity properties for example as a copper wire in electric motors, transformers, electrical cables, circuit boards (they are 20% copper) and so on.

Pure copper can be recycled locally in WA, however, local demand is limited therefore the majority of metal is exported. We work with a number of local and international vendors to export copper and copper derivatives directly to smelters and reprocessing facilities in Japan, Malaysia, India and Indonesia.

Copper is one of the most valuable materials we recover, second to precious metals such as gold and silver from circuit boards.

Copper can also be infinitely recycled and like aluminium, recycling has a lower environmental impact when compared to raw extraction and refining, so it’s important we recover as much as possible for reuse.

Brass

Brass is an alloy of copper and zinc. It can be confused with gold because of its golden colour. Unfortunately for us, it is worth orders of magnitudes less than gold.

It’s found in any cooling circuit fittings or pressure vessels, anything with plumbing, air-conditioners and things like liquid-cooled PCs as it has good thermal conductivity properties with the added benefit of strength.

We recover brass much the same way as we recover any of the other non-ferrous metals through the presorting process, picking it off the picking line after shredding and separating it from the material stream using our eddy current separator and optical sorter.

Brass like many of the other non-ferrous metals has a high level of recyclability and it is beneficial environmentally to recycle it when compared with the raw material process.

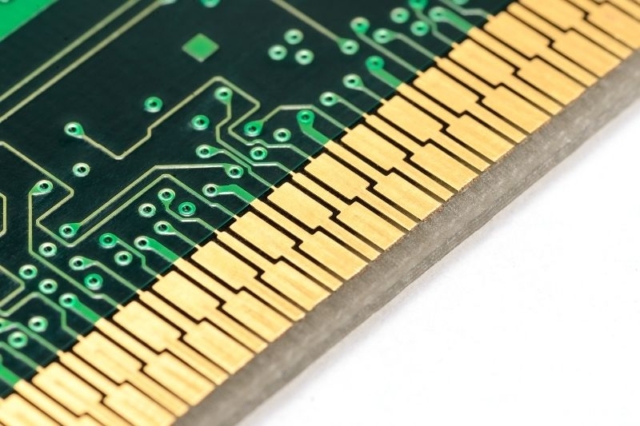

Precious metals such as gold

Precious metals are mainly found in circuit boards and data connection point like data cable plugs. They’re usually used for their superior electrical conductivity properties and stability as they are relatively inert. They’ll be typically used on contact points and as the miniature wiring inside an integrated circuit chip.

We recover gold, silver, platinum, palladium along with copper from printed circuit boards found in electronics.

We cooperate with Japanese smelters such as the Mitsubishi smelter to recover these metals directly from circuit boards we send to them. They use a zero-waste process using the resin and plastic as a fuel source, capturing all emissions and using bottom ash as a construction product. The smelter also produces acid from the captured fumes which then can be used to manufacture goods such as lead-acid batteries.

In 2021, we recovered approximately 6 kg of gold, 37.5 kg of silver from circuit boards.

Metals recovered from circuit boards in Japan were used to make medals for the 2020 Olympics. They can also be used to make new electronics or jewellery.

Non-leaded and leaded glass

You can learn the difference between leaded and non-leaded glass in our previous article.

Leaded glass goes to Port Pirie in SA which is one of the world’s largest primary lead smelting facilities and the third largest silver producer.

Non-leaded glass can be found in printers, front panels of CRT TVs, microwaves and some other white goods.

Here in WA glass is currently crushed and used in our roads as it’s economically not viable to transfer it down to South Australia’s glass smelter. (WA doesn’t have any yet.). The glass recovered from electronics could not be used in the South Australia smelter as this smelter produces beverage glass, which has a different compositional makeup than that recovered from glass found in electronics.

Glass to glass recycling is the best option for recovered glass when looking at the process in isolation, however, factors such as logistics and market demand weaken this argument. We have found recycling glass into construction aggregate the best option available to us in here in WA.

Paper/cardboard

While paper and cardboard are not common items in e-waste, we receive these materials in the form of packaging. We separate and bale the recovered paper and cardboard and work with third parties to transport the material over east or overseas where it will be made into new packaging.

We kindly ask anyone delivering to us to remove packaging prior to delivery as it adds complexity and cost to our process.

Batteries

We recover approximately 30 tonnes of batteries from e-waste every year. This includes all types of batteries. From lead-acid batteries found in uninterruptable power supplies (UPS) to lithium-ion laptop batteries and everything in between. Electronic manufacturing has been trending towards mobile devices with integrated batteries for some time and we are seeing the battery volumes we recover grow year on year.

Recovered lead-acid batteries go to Energi power storage recycling in Wagga Wagga in NSW. They use advanced recycling technology to convert Used Lead Acid Batteries (ULAB) into lead, polypropylene and sodium sulphate for reuse. (Bonus article:

Where Recycled Material Goes)

Other batteries go to Envirostream in Victoria where they can recover more than 95% of the resources from end-of-life batteries. Things like steel, copper, aluminium and a mixed metal compound.

For more info read our article What happens to batteries we recover from e-waste.

Plastic

E-waste is approximately 21% plastic by weight. The type of plastics used to make electronic devices vary depending on the material properties needed for each part or assembly. The more common types of polymers found in electronics are:

• Polyethylene (PE)

• Acrylonitrile butadiene styrene (ABS)

• Polystyrene (PS)

• Polypropylene (PP)

• Polyvinyl chloride (PVC)

• Nylon or polyamide. (PA)

For an overview of the types of plastics we recommend, the article The seven types of plastic. E-waste contains a lot of plastics in the 7 category or other.

In 2019 we received a grant from the WA Waste Authority for an optical sorter to help us better separate plastic. The new machine uses compressed air to remove contaminants from our recovered plastic fraction and is able to recognise contaminants by colour and shape.

The contaminates we target are glass, electrical cable and printed circuit board, which are all recycled once removed from the plastic stream.

Majority of our plastic is exported at present due to the lack of plastic recyclers in the WA market, however, we are exploring local options for some of the plastics we separate such as PP, PE and PMMA.

The current destination for our recovered plastics is reprocessors in countries abroad like Hong Kong and Malaysia.

We hope one day we won’t have to rely on export and will be able to establish a local circular process for all materials we recover, not just plastic.

Ink and toner

We recover a significant amount (50 tonnes/year) of ink and toner cartridges from printers and photocopiers.

We send this material to the Close The Loop in Victoria.

Close the loop transforms this material through their specialised processed into an asphalt additive called TonerPave. This product has a high-recycled content and reduced carbon footprint when compared to standard asphalt.

Wood

We receive wood in the form of old-school televisions, audio equipment and pallets that e-waste is delivered to us on.

We pay EMRC’s Hazelmere wood recycling facility to process the wood where it is turned into animal bedding and other products.

Fluorescent light globes

Fluorescent light globes are typically found in flat-screen TVs as the light source in the TV that helps generate the picture you see on your screen. Fortunately, innovation has advanced display technology to a LED (Light Emitting Diode) solution replacing the mercury-containing fluorescent tube as the light source. LED TVs unlike CCFL flatscreen TVs do not contain mercury which is toxic to our environment.

We separate cold cathode fluorescent lamps (CCFL) through a manual disassembly process and send them to a specialised mercury recycler in WA. After a crushing process, the material is then sent to Victoria for further processing through a mercury distillation process.

Thanks for reading and please let us know if you have any questions or would like to cooperate on closing the loop on any of these (or other not-mentioned) materials we recover from e-waste.

Hey guys! This is a really great article – very methodically laid out and a great level of detail. It’s also reassuring to know you send much of your material first to WA destinations, then onto other places. And that you continue to explore better destinations.

I’ve read in the past of raw (whole) e-waste being sent from other Australians sources to the developing world where it is broken down for resource recovery in unsafe practices, using unfair work places. That you separate out your basic materials in WA before sending them on to other places is very reassuring.

Thank you.

Glad you are continuing to reduce ewaste in land fill.

I enjoyed finding out about the complexity of the processes you use.

Good on you and keep it up!

Very interesting. Thank you for this. It’s absolutely essential however that we do more recycling right here in WA insted of transporting waste material to the E. States and overseas. I know you’re lobbying to make this happen. I think I’ll drop an email to my local MP!

I’m trying to find someone who will buy off of me circuit boards from

Microwaves/tvs/dvdplayers/computers/washing machines dryers etc.

I can’t find anywhere in South Australia do you know anywhere?

Kind regards

Duncan

Hey Duncan,

You should try to get in touch with Electronics Recycling Australia, they do e-waste recycling in South Australia and might be able to help you out.

Thanks!